Spherical roller thrust bearings have specially designed raceways and asymmetric rollers. Bearings can withstand axial loads acting in one direction and radial loads acting simultaneously. The load is transferred between the raceways through the rollers at an angle to the bearing axis, while the ribs guide t...

Check Detail

Tapered roller thrust bearings can withstand heavy axial loads and peak loads. The bearings are highly rigid and require little axial space. Bearing Features: Separate Design The shaft and housing washers and roller and cage thrust assemblies of tapered roller thrust bearings with cages can be installed sepa...

Check Detail

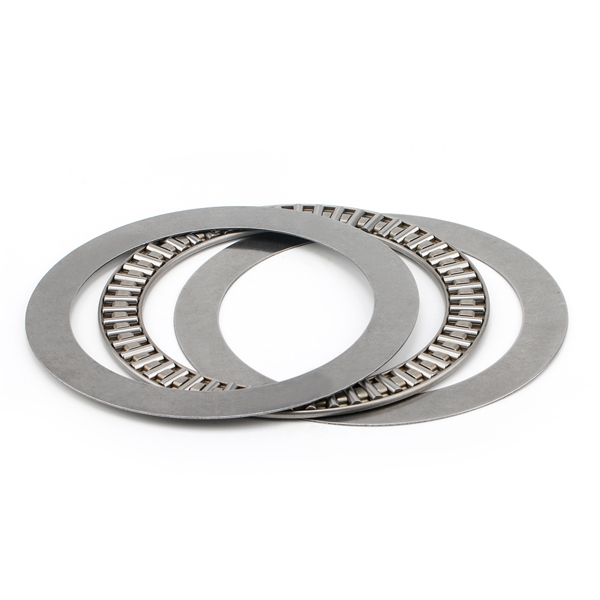

Needle roller thrust bearings are equipped with a shaped cage that can reliably fix and guide a large number of needle rollers. Needle roller thrust bearings provide very high stiffness in a very small axial space. In applications where adjacent machine component surfaces can be used as raceways, needle roller...

Check Detail

Cylindrical roller thrust bearings can withstand heavy axial loads and impact loads. Such bearings must not bear any radial load. The bearings are highly rigid and require little axial space. Bearing features: Separable design This means that the shaft washers, seat washers and cylindrical roller-cage assem...

Check Detail

Spherical roller bearings have two rows of symmetrical rollers. The outer ring has a common spherical raceway, and the inner ring has two raceways at an angle to the vertical axis of the bearing. The center of the outer ring spherical raceway is located on the bearing shaft. Bearing Characteristics: Mis...

Check Detail

Four-row tapered roller bearings can accommodate combined low- and medium-speed (radial and axial) loads. They are used almost exclusively in roll applications such as rolling mills. Bearing Features Depending on their design, four-row tapered roller bearings offer the following key features and benefit...

Check Detail

Due to their design, these bearings can withstand heavy radial loads, axial loads in both directions and are highly rigid. Double row tapered roller bearings are commonly used in gearboxes, lifting equipment, rolling mills and mining machinery such as tunnel boring machines. Bearing characteristics: High l...

Check Detail

The products of matched single row tapered roller bearings are based on the common dimensions of single row tapered roller bearings. Depending on the application requirements, matched tapered roller bearings are available in different designs and variants: Bearing characteristics: High load-bearing capacity...

Check Detail

Single row tapered roller bearings are designed to accommodate combined loads, i.e. radial and axial loads acting simultaneously. The extension lines of the raceways meet at the same point on the bearing axis to achieve true rolling and therefore low friction torque during operation. The axial load capacity...

Check Detail

Needle roller bearing inner rings Inner rings are supplied separately for needle roller bearings. In applications where the shaft cannot be hardened and ground, needle roller bearing inner rings are often used in combination with needle roller and cage assemblies or with drawn outer ring needle roller bearings. ...

Check Detail

Universal joint bearings are manufactured from cold forged or machined needle roller bearings with closed ends for a variety of applications. They are used in the automotive industry, commercial vehicle propeller shafts and other industries for joints for special applications. Universal joint bearings come i...

Check Detail

The cylindrical roller and cage thrust assembly consists of radial needle roller bearings and cylindrical roller thrust bearings. Delivered without inner ring Can be combined with an inner ring in applications where the shaft cannot be hardened and ground Can withstand axial loads in one direction Can positi...

Check Detail

Consists of radial needle roller bearings and thrust ball bearings. Delivered without inner ring. In applications where the shaft cannot be hardened and ground, the bearing should be used in conjunction with an inner ring that can support axial loads in one direction and therefore can only position the shaft. Whe...

Check Detail

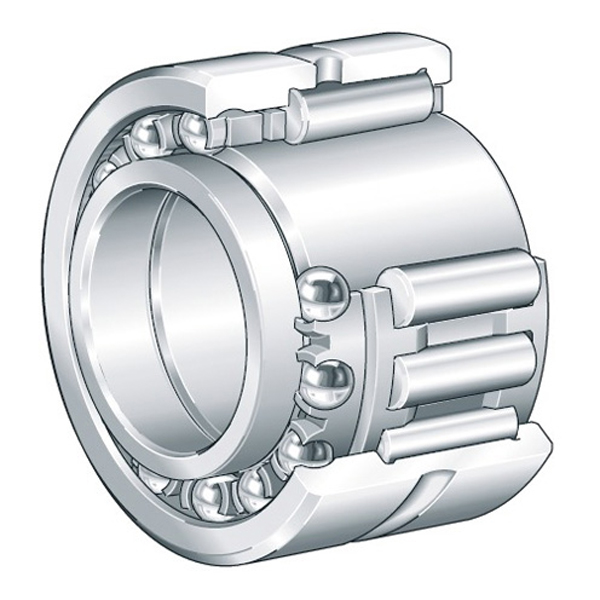

It is composed of radial needle roller bearings and angular contact ball bearings. It can bear the heavy radial load caused by the needle roller bearing and adapt to the light axial load. The low-section bearing can be carried by the angular contact ball bearing and can run at high speed. They are all separate bear...

Check Detail

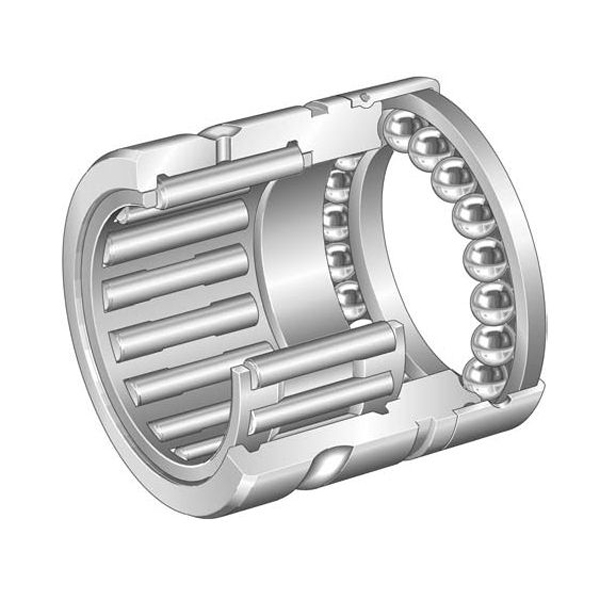

Combined needle roller bearings are composed of radial needle roller bearings and thrust bearings. They can withstand both radial and axial loads. Combined needle roller bearings are particularly suitable in applications where other types of locating end bearing arrangements take up too much space or where t...

Check Detail

The outer circle of the spherical needle roller bearing is designed as a convex spherical surface. Two polymer seats with an outer concave spherical design are combined in a stamped steel ring and installed on the outer ring. Bearing characteristics: Adaptation to static misalignment Spherical needle roller...

Check Detail

Needle roller bearings with machined rings are made of high carbon chromium bearing steel. Needle roller bearings are available in various series and sizes or without ribs on the outer ring. Also available with or without inner ring. Bearing characteristics: Low cross-section Needle roller bearings offer...

Check Detail

Drawn cup needle roller bearings have a deep-drawn thin-walled outer ring. Drawn cup needle roller bearings are typically used in applications where the housing bore cannot be used as a raceway for the needle roller and cage assembly, but a very compact and economical bearing arrangement is required. These...

Check Detail

The needle roller and cage assembly is independent and is a quick-install bearing unit. In applications where the shaft and housing bore can serve as raceways, components can be used to create bearing configurations that require minimal radial space. Bearing characteristics: Lowest cross-section among rollin...

Check Detail

Split cylindrical roller bearings are primarily used in bearing arrangements that are difficult to access or on crankshafts. The use of all grades of the above-mentioned bearings is advantageous when maintaining or replacing integral bearings would require considerable time-consuming additional effort and res...

Check Detail

Double row full complement cylindrical roller bearings contain the largest number of rollers because they have no cage. The basic products offered here include: Open bearings in three different designs: Type NNCL Type NNCF Type NNC Type NNF Sealed bearings Bearing characteristics: High load-...

Check Detail

Single row full cylindrical roller bearings contain the largest number of rollers because they are not equipped with a cage. The basic product categories available here include: NCF type bearings NJG type bearings Bearing characteristics: High load-bearing capacity Bearings without cages can accommodat...

Check Detail

Four-row cylindrical roller bearings are available in many different designs. With cylindrical or tapered bore, open or sealed, four-row cylindrical roller bearings are almost exclusively used in the roll necks of rolling stands, calenders and roller presses. Since these bearings are typically mounted with an ...

Check Detail

Double row cylindrical roller bearings are available in various designs with cylindrical or tapered bores. Standard products offered in this section include: NNU type bearings NN type bearings NNUP type bearings Bearing characteristics: High load carrying capacity Double row cylindrical roller bearings...

Check Detail

High load capacity cylindrical roller bearings have the high load capacity of full roller bearings and the high speed capabilities of cage bearings. They are designed for applications such as industrial gearboxes, wind turbine gearboxes and mining equipment. Bearing characteristics: High load carrying capacity T...

Check Detail

Single row cylindrical roller bearings are available in a variety of designs, series and sizes. The main design differences between the bearings presented in this section are: Cage design and materials Arrangement of inner and outer ring flanges Bearing characteristics: Low friction (roller end/flange conta...

Check Detail