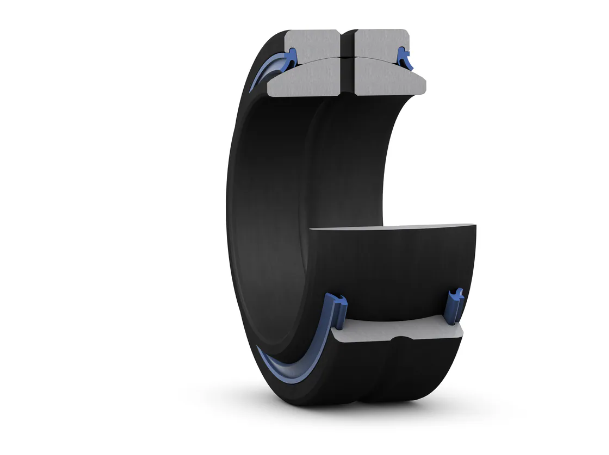

Self-lubricated (Lubricated) bearings are bearings filled with special solid lubricants and are specially designed for dust conditions in the atmosphere.

Check Detail

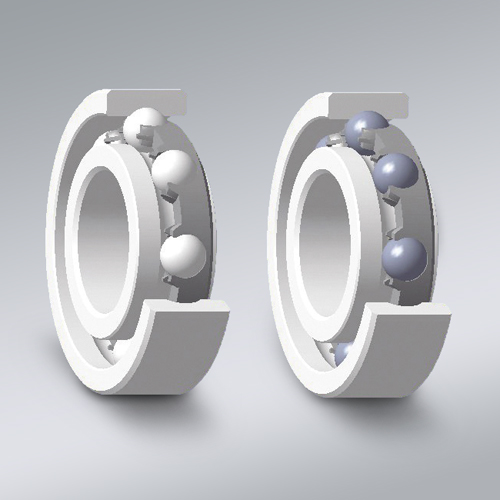

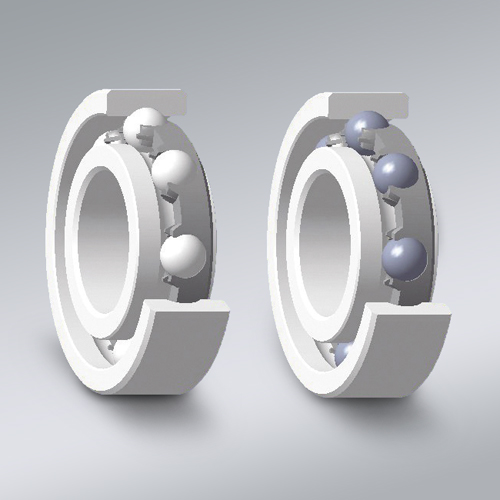

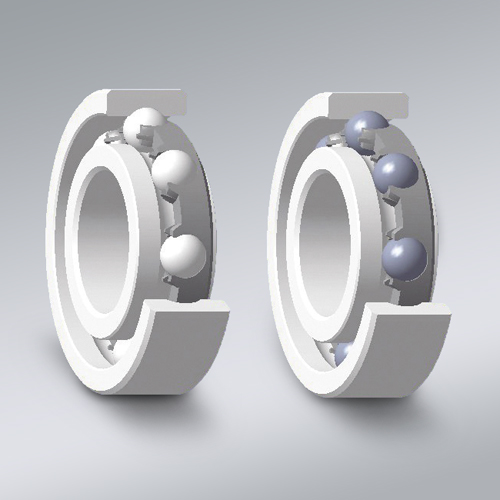

This is a bearing in which the inner and outer rings and balls are made of ceramic materials, and a fluorine-based solid lubricated cage is used to achieve lubrication effect. It is suitable for corrosive working conditions and non-magnetic working conditions in the atmosphere to vacuum.

Check Detail

Titanium alloy bearings are completely non-magnetic (relative magnetic permeability lower than 1.001) bearings with inner and outer rings made of special titanium alloy materials and ceramic balls. They are suitable for non-magnetic working conditions in atmosphere to vacuum.

Check Detail

ESA bearings are made of "austenitic stainless steel plus a surface hardened layer" and have the characteristics of high hardness, super corrosion resistance, and non-magnetic properties. Suitable for corrosive working conditions and non-magnetic working conditions in atmosphere to vacuum.

Check Detail

YS-type bearings use new materials for solid lubricating cages. They have the characteristics of cleanliness and longevity, and are suitable for clean working conditions in atmosphere to vacuum.

Check Detail

The inner and outer rings, balls and cages of DFO bearings have been treated with low-pressure steam hydrocarbon coating (E-DFO) and fluorine oil coating. It is a new concept bearing with cleanliness and long life. Suitable for various clean environments from atmosphere to vacuum.

Check Detail

This is a stainless steel bearing filled with fluorine-based pure grease DL2, specially designed for clean working conditions in atmosphere to vacuum.

Check Detail

This is a stainless steel bearing filled with NSK pure grease LG2 and LGU, which is specially designed for clean working conditions at room temperature in the atmosphere.

Check Detail

This is a bearing in which the inner and outer rings and balls are made of ceramic materials, and a fluorine-based solid lubricated cage is used to achieve lubrication effect. It is suitable for corrosive working conditions and non-magnetic working conditions in the atmosphere to vacuum.

Check Detail

ESA bearings are made of "austenitic stainless steel plus a surface hardened layer" and have the characteristics of high hardness, super corrosion resistance, and non-magnetic properties. Suitable for corrosive working conditions and non-magnetic working conditions in atmosphere to vacuum.

Check Detail

Titanium alloy bearings are completely non-magnetic (relative magnetic permeability lower than 1.001) bearings with inner and outer rings made of special titanium alloy materials and ceramic balls. They are suitable for non-magnetic working conditions in atmosphere to vacuum.

Check Detail

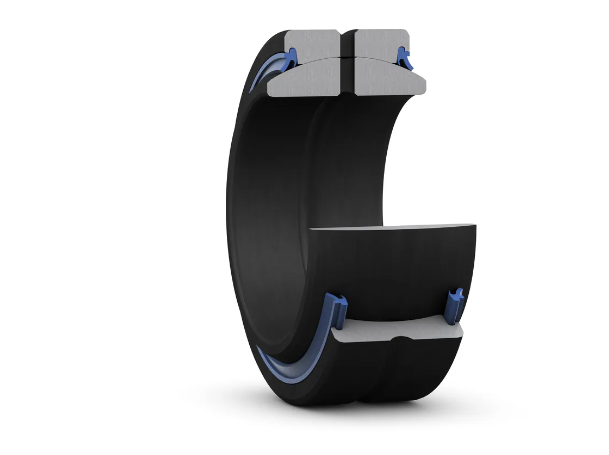

The high-temperature-resistant SJ type bearing is a bearing product with a "bean" structure with a solid lubricating spacer sandwiched between two rolling elements in each pocket of the cage. This kind of bearing is suitable for vacuum and high temperature working conditions.

Check Detail

The high-temperature-resistant YS type bearing is a bearing with an alloy solid lubricating material (powder metallurgy) spacer installed between the rolling elements. It is suitable for vacuum and high-temperature working conditions.

Check Detail

YS-type bearings use new materials for solid lubricating cages. They have the characteristics of cleanliness and longevity, and are suitable for clean working conditions in atmosphere to vacuum.

Check Detail

The inner and outer rings, balls and cages of DFO bearings have been treated with low-pressure steam hydrocarbon coating (E-DFO) and fluorine oil coating. It is a new concept bearing with cleanliness and long life. Suitable for various clean environments from atmosphere to vacuum.

Check Detail

Hybrid bearings are mixed bearings made of ceramic balls and fluorine-based solid lubricated cages, and are specially designed for atmospheric to vacuum corrosion conditions.

Check Detail

This is a stainless steel bearing filled with fluorine-based pure grease DL2, specially designed for clean working conditions in atmosphere to vacuum.

Check Detail

This is a new type of bearing whose inner and outer rings and cage are made of special fluorine-based resin materials. This product can exert its advantages in working conditions such as high water, alkaline, strong acid, etc., and is specially used for corrosive conditions in the atmosphere.

Check Detail

This is a bearing in which the inner and outer rings and balls are made of ceramic materials, and a fluorine-based solid lubricated cage is used to achieve lubrication effect. It is suitable for corrosive working conditions and non-magnetic working conditions in the atmosphere to vacuum.

Check Detail

ESA bearings are made of "austenitic stainless steel plus a surface hardened layer" and have the characteristics of high hardness, super corrosion resistance, and non-magnetic properties. Suitable for corrosive working conditions and non-magnetic working conditions in atmosphere to vacuum.

Check Detail

ESZ bearings have stronger corrosion resistance than martensitic stainless steel bearings. It has the same corrosion resistance as precipitation hardened stainless steel, but its hardness is more than 30% higher, making it suitable for atmospheric corrosive environments.

Check Detail

Corrosion-resistant coated bearings are bearings whose inner and outer rings are plated with nickel film to enhance corrosion resistance and durability. They are suitable for corrosion conditions in the atmosphere and high temperatures.

Check Detail

Hybrid bearings are mixed bearings made of ceramic balls and fluorine-based solid lubricated cages, and are specially designed for atmospheric to vacuum corrosion conditions.

Check Detail

Self-lubricated (Lubricated) bearings are bearings filled with special solid lubricants and are specially designed for corrosive conditions and dust conditions in the atmosphere.

Check Detail

Stainless steel bearings are one of the basic types of WSN's SPACEATM series of special bearings for special working conditions. They are specially used in high-humidity working conditions, with sufficient supply and fast supply.

Check Detail

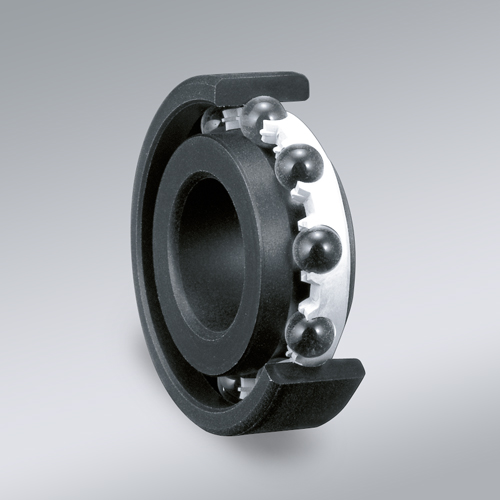

Polymer ball bearings consist of: ? Polymer rings ? Balls made of stainless steel, glass, polymer or other materials and ? A polymer cage. Polymer ball bearings can be made from a variety of materials and material combinations. The materials selected depend on the application. Polymers have signifi...

Check Detail

Special lubricating oil for food machinery is used.

Check Detail

Bearings with special grease for food machinery encapsulated in stainless steel bearings are suitable for food machinery, pharmaceutical machinery and other industries. An internationally recognized U.S. third-party certification body in the field of public safety and health.

Check Detail

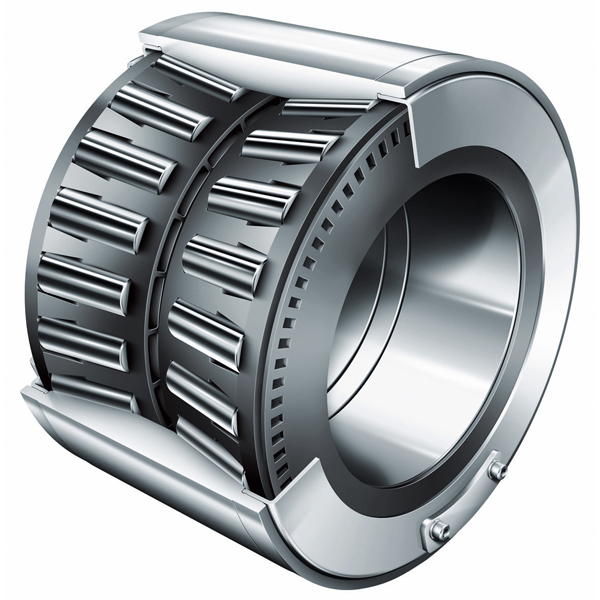

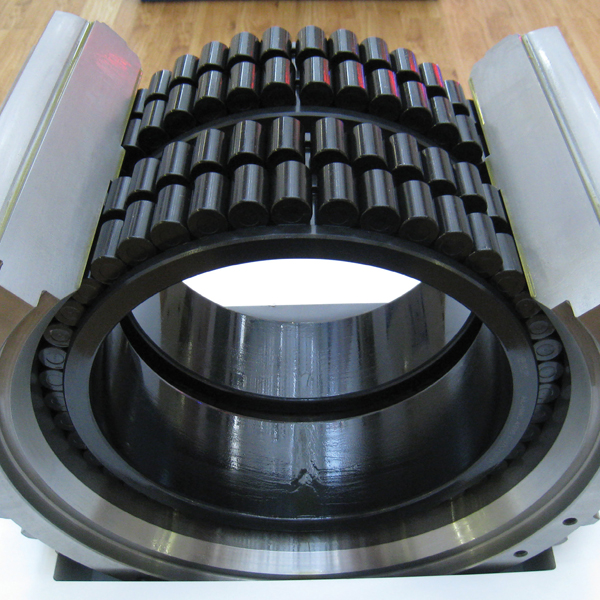

High load-bearing capacity Thick outer ring walls are able to withstand high radial loads while reducing deformation and bending stresses. Due to their ribs on the inner ring, the support roller units can also withstand heavy axial loads. The maximum number of rollers in double- and four-row cylindrical r...

Check Detail

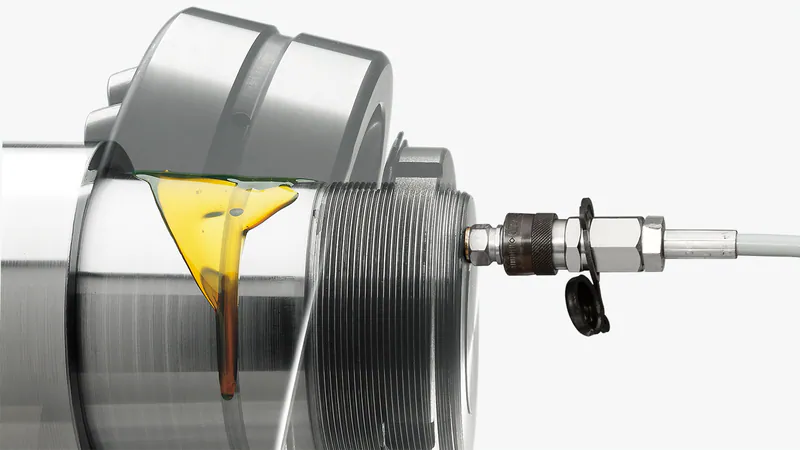

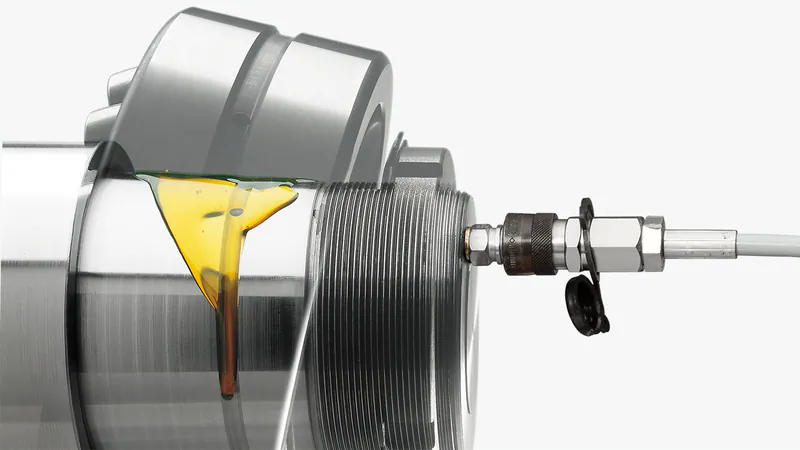

Long Service Life Increased operating temperatures push oil towards the surface of the polymer material, supporting a constant supply of lubricant. When out of service, any excess lubricant will be drawn back into the polymer material. Extended Bearing Life With solid oil bearings, large amounts of oil...

Check Detail

Long service life Withstands a wide range of extreme conditions Higher risk of adhesive wear Insufficient lubricant film Rapidly changing loads Light loads Rapidly changing rotational speeds Vibrations and oscillations

Check Detail

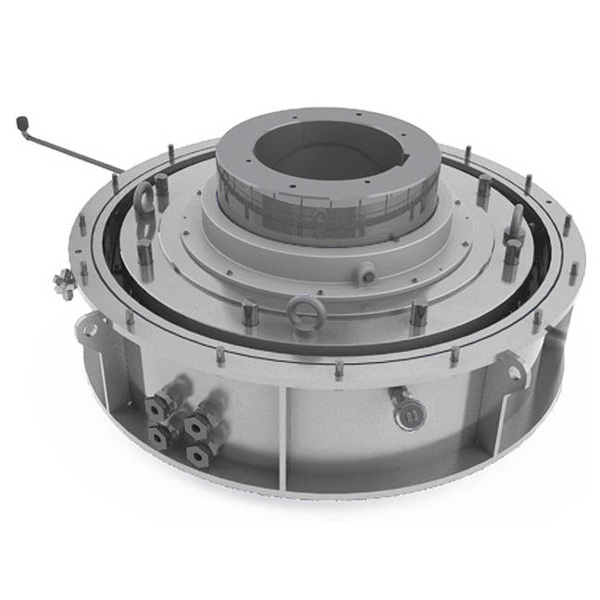

Reduced total operating costs The bearings are designed to maintain the radial clearance required for high-temperature operation while ensuring they will not seize, even under rapid cooling, thereby achieving the goal of extended service life. Virtually maintenance-free operation The bearings are lubricated fo...

Check Detail

Resistant to Galvanic Corrosion With insulation properties integrated into the bearing, INSOCOAT bearings can improve reliability and increase machine uptime by virtually eliminating the problem of galvanic corrosion. High resistance The aluminum oxide coating has a minimum resistance of 200MΩ ...

Check Detail

Silicon nitride rolling elements provide higher bearing performance even under difficult operating conditions, thus extending bearing life. Advantages of hybrid ceramic bearings compared to bearings with steel rolling elements include: Protection against damage caused by electrical current Hybrid ceramic be...

Check Detail

Integrated sensor solutions have already proven themselves in a variety of industrial and automotive applications, such as electric motors, electric vehicles, road rollers, tractors, forklifts and conveyors. Typical applications include: Motor management Steering Speed and position sensing Angular position m...

Check Detail

High load carrying capacity Low friction Optimized internal geometry reduces bearing friction and heating; Long service life Logarithmic profile reduces edge stresses at the roller/raceway contact under all load conditions (Fig. 2). Furthermore, the logarithmic outer ring outer diameter profile reduces e...

Check Detail